What is Directional Drilling

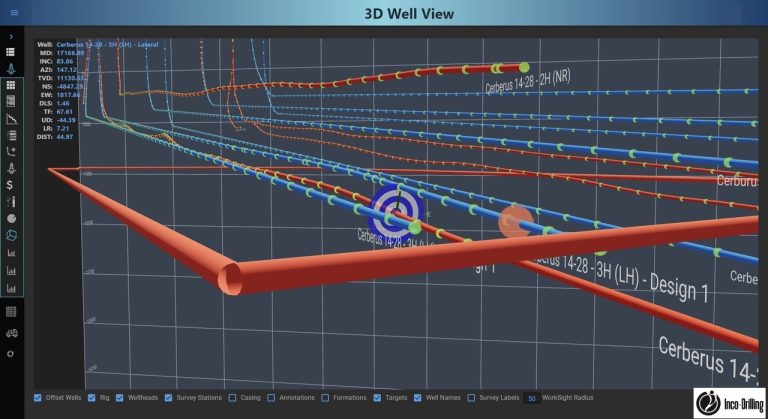

Directional drilling is a technique used to drill non-vertical wells. Instead of drilling straight down, directional drilling allows the well to be drilled at different angles, including horizontal and inclined paths, to reach reservoirs that cannot be accessed with vertical drilling alone.

This technique involves the use of specialized equipment such as downhole motors, measurement-while-drilling (MWD) tools, and rotary steerable systems to control the direction and trajectory of the wellbore. By steering the drill bit along a predetermined path, specific targets beneath the earth’s surface can be reached.

Directional drilling offers several advantages, including:

- Increased access to reservoirs: By drilling horizontally or at specific angles, directional drilling enables access to a larger portion of the reservoir, which can enhance production rates and overall recovery.

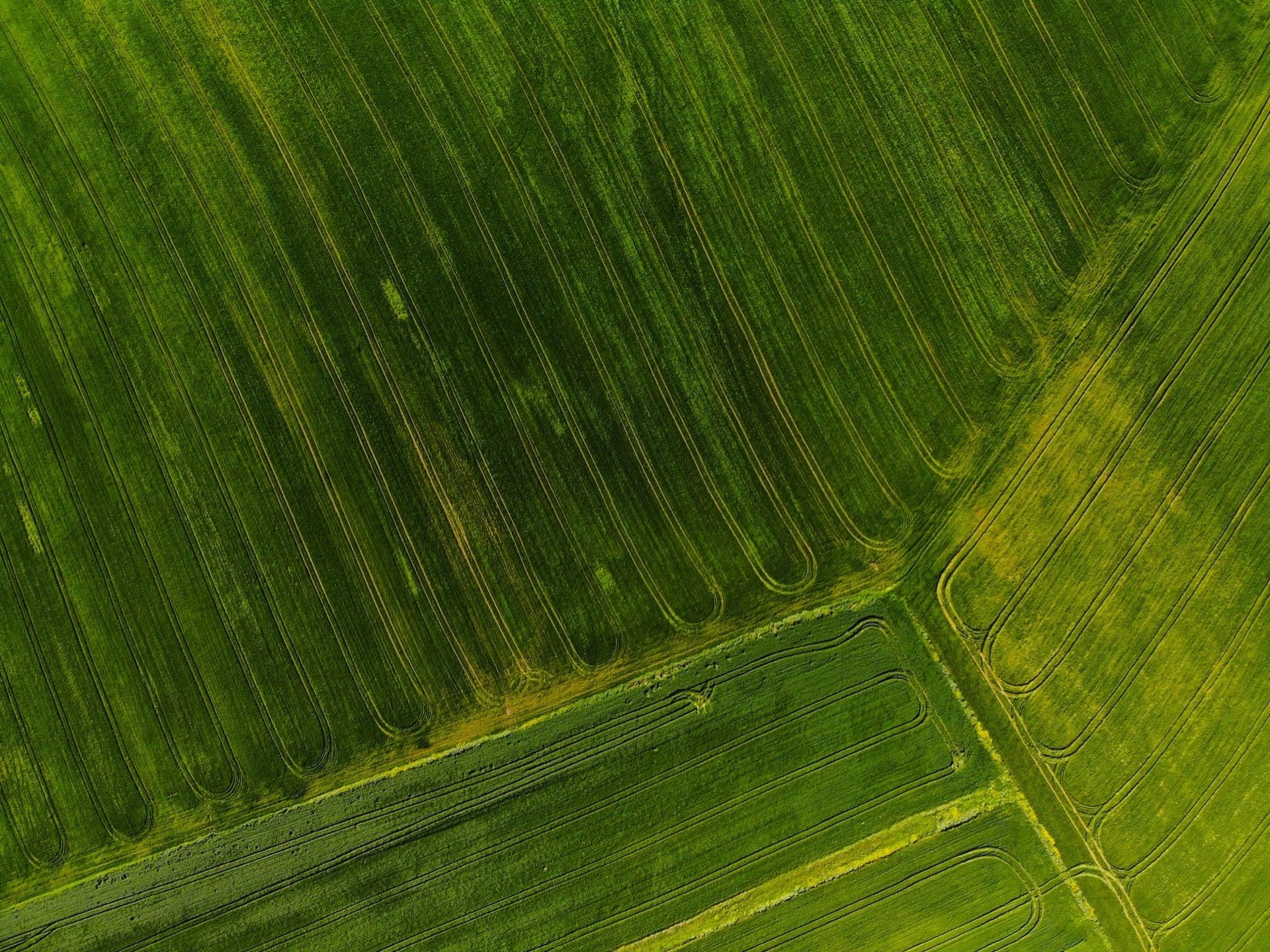

- Reduced environmental impact: Directional drilling allows to minimize surface disturbance by accessing multiple locations from a single drilling pad, reducing the footprint of drilling operations.

- Enhanced wellbore stability: By drilling along natural geological formations, directional drilling can help mitigate challenges such as unstable formations or wellbore collapse.

- Improved reservoir management: Directional drilling help to optimize well placement within the reservoir, maximizing contact with target formations and improving reservoir drainage efficiency.

- Overall, directional drilling plays a crucial role in the exploration and production of geothermal, mining, gas storage and hydrocarbons resources, allowing to reach the resources from complex geological formations more efficiently and economically.

With more than 60 drilled wells across all Europe, Inco-Drilling provides directional drilling services through the use of:

Our services

| Equipment

|