Our Technology

Inco-Drilling specializes in providing advanced Directional Drilling services tailored to the unique demands of geothermal, natural gas, mining and energy storage wells. Our team of highly skilled engineers and professionals leverages state-of-the-art technology and experience to deliver precise and efficient drilling solutions. By optimizing well trajectories and developing mitigation strategies, we minimize drilling time, helping our clients to achieve wells on target, on time and within budget.

What is Directional Drilling?

Directional drilling is a technique that allows drilling at various angles, including vertically and horizontally, to reach subsurface targets located away from the drill site. This contrasts with conventional drilling, which produces an uncontrolled well trajectory that could miss the energy reservoir.

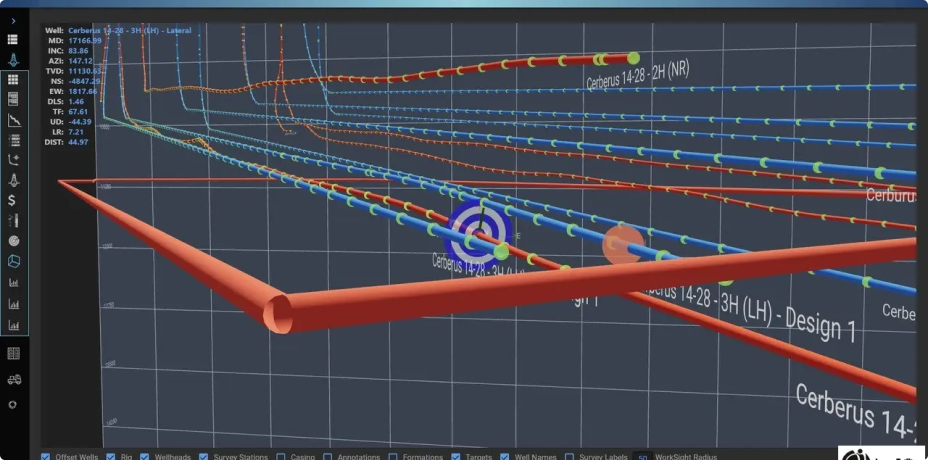

Directional drilling uses specialized tools such as rotary steerable systems (RSS) and downhole steerable motors to precisely control the drill bit’s trajectory. These tools, combined with advanced measurement-while-drilling (MWD) technologies, provide real-time information about the wellbore’s position and orientation, allowing our personnel to make precise adjustments to the drilling path.

The ability to control the drilling direction makes directional drilling essential for accessing resources and achieving project objectives in challenging geological formations. It is widely applied in industries such as geothermal energy, natural gas exploration, and for environmental purposes like installing underground utilities.

Technical Benefits of Directional Drilling

1. Increased Reach and Access : Directional drilling allows for precise steering of the drill bit, enabling access to resources or target locations that are not directly beneath the drilling site. This capability is particularly beneficial in reaching geothermal reservoirs, bypassing obstacles, or connecting to multiple underground targets from a single entry point.

2. Multi-Well Drilling from a Single Site: With directional drilling, multiple wells can be drilled from a single surface location, reducing the need for additional drilling sites. This approach increases efficiency, minimizes surface disruption, and optimizes the use of infrastructure.

3. Enhanced Resource Recovery: By accurately positioning the drill path within targeted zones, directional drilling ensures maximum resource extraction, whether it’s geothermal energy, natural gas, or other underground materials. This precision minimizes wastage and enhances overall project viability.

4. Minimized Surface Disruption: Directional drilling significantly reduces the environmental impact of projects. By avoiding the need to dig trenches or create large surface disturbances, it preserves natural landscapes, reduces rehabilitation costs, and complies with environmental regulations.

5. Improved Accuracy Through Advanced Technology: Modern directional drilling uses advanced decoding telemetry and navigational systems for precise tracking and control. This ensures that the drill path follows the exact planned trajectory, reducing the risk of errors and rework.

Monetized Benefits of Directional Drilling

Reduced Project Costs

Maximized Resource Extraction

By precisely targeting underground resources, directional drilling ensures optimal recovery of geothermal heat, natural gas, or other materials. This increases the revenue potential and overall profitability of the project.

Faster Project Timelines

Environmental Compliance Savings

Directional drilling’s minimal surface impact reduces costs associated with environmental permitting, mitigation efforts, and land rehabilitation, streamlining the approval process and saving money.

Access to Inaccessible Resources

Core Services Inco-Drilling offers with Directional Drilling

- Well Positioning: Precisely locating and targeting subsurface formations.

- Side-Tracking: Diverting a wellbore to a new trajectory.

- Coal Mine Intersection: For repurposing old mines to geothermal heating and cooling systems.

- Anti-Collision: Mitigating the risk of wellbore collisions while maximizing extraction.

- Engineering & Planning: Designing optimal well trajectories and developing mitigation strategies of drilling risks.

- Hydro Wells: Placing wells within meters of mine shafts for water influx monitoring.

- Volcanic Drilling: Specialized drilling techniques for volcanic environments.

- Magnetic Ranging: Employing advanced magnetic tools for accurate wellbore positioning.

To deliver superior results, we use state-of-the-art Technology

• Steerable Motors: Control the deviation and trajectory of the wellbore with mud motor technology

• Rotary Steerable Systems (RSS): Advanced steering technology for precise wellbore placement

• Measuring While Drilling (MWD): Real-time measurement of downhole conditions

• Logging While Drilling (LWD): Measurement of downhole geological and drilling properties

• Drop Gyro: High-precision inclination and azimuth measurement tools for environments with magnetic interference

• Gyro While Drilling (GWD): Continuous real-time measurement of wellbore orientation

• Drilling Enhancement: Innovative techniques to optimize drilling performance

• Advanced Drill Bits: Cutting-edge bit technology for efficient drilling