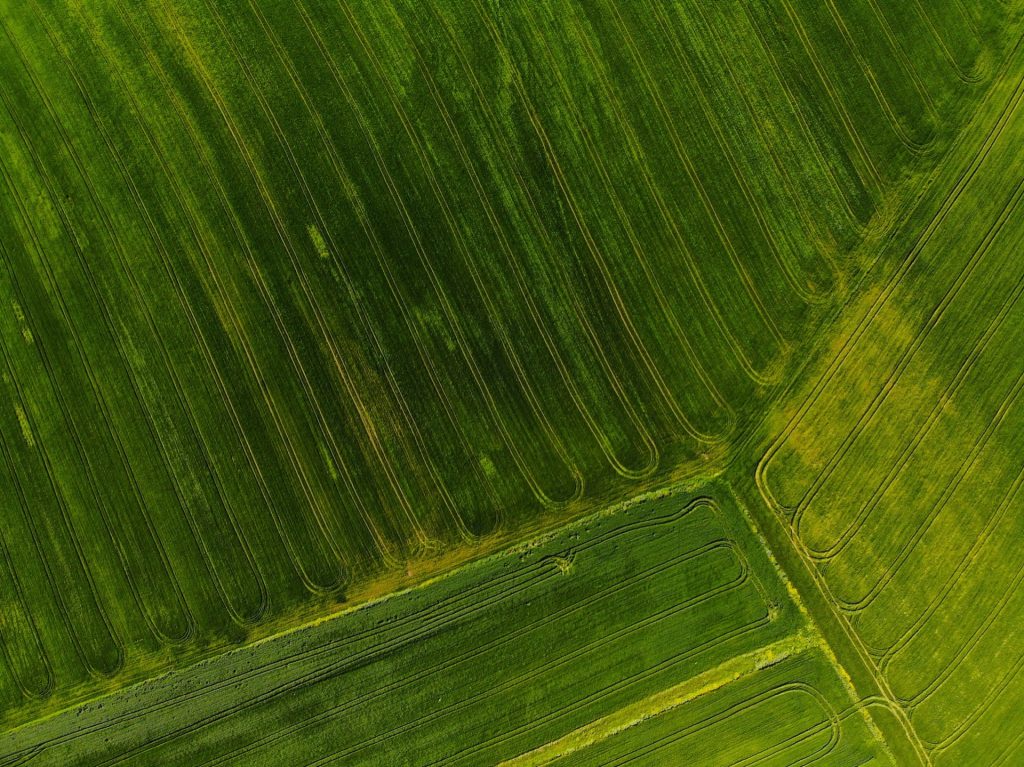

Geothermal Energy

Empower a carbon-neutral future with efficient and flexible drilling solutions for geothermal wells. Choose Inco-Drilling for reducing drilling risks and high liabilities.

We are dedicated to contributing to a more balanced future through the use of efficient technology in geothermal, gas, underground storage and mining.

Watch the videoWe are at the forefront of the drilling industry, utilizing the latest in cutting-edge technology and expert professionals to deliver unparalleled results.

Our flexible and adaptable approach to drilling allows us to effectively respond to any changes or challenges that may arise during a project.

With coverage throughout Europe and a proven track record of success, Inco-Drilling is the trusted choice for drilling projects of all sizes and complexities.

Our cost-efficient solutions deliver higher performance that set us apart from the competition, contributing that projects are completed on time and within budget.

Empower a carbon-neutral future with efficient and flexible drilling solutions for geothermal wells. Choose Inco-Drilling for reducing drilling risks and high liabilities.

Efficient and custom-made designs for extraction or storage of gas, including CO2 storage. Choose Inco-Drilling for operational excellence.

Precise designs and precise execution to reach the smallest targets underground. Choose Inco-Drilling for precise drilling.